The Porsche 928 is not an immediate Porsche. Understanding it today means aligning expectations, engineering and method before the purchase itself.

Read morethe hangout of porsche lovers

MAVMENT BLOG

News Insights restorations

News Insights restorations

The Porsche 928 is not an immediate Porsche. Understanding it today means aligning expectations, engineering and method before the purchase itself.

Read moreWhen Porsche meets art, the automobile becomes a cultural language. An exploration of design, museums, and collaborations beyond the surface.

Read moreHow to properly store a Porsche during winter: engine, battery, tyres and garage conditions explained for classic, youngtimer and modern models.

Read moreAn in-depth look at Porsche watches as technical instruments, from functional design to materials and movements, rooted in the brand’s engineering culture.

Read moreA technical deep dive into hi-tech materials used in Porsche supercars, from titanium to magnesium and carbon fiber, and how they define performance, reliability and...

Read moreLooking for a sports car that can handle the snow? Here are the perfect models to enjoy winter driving without compromising on performance.

Read more

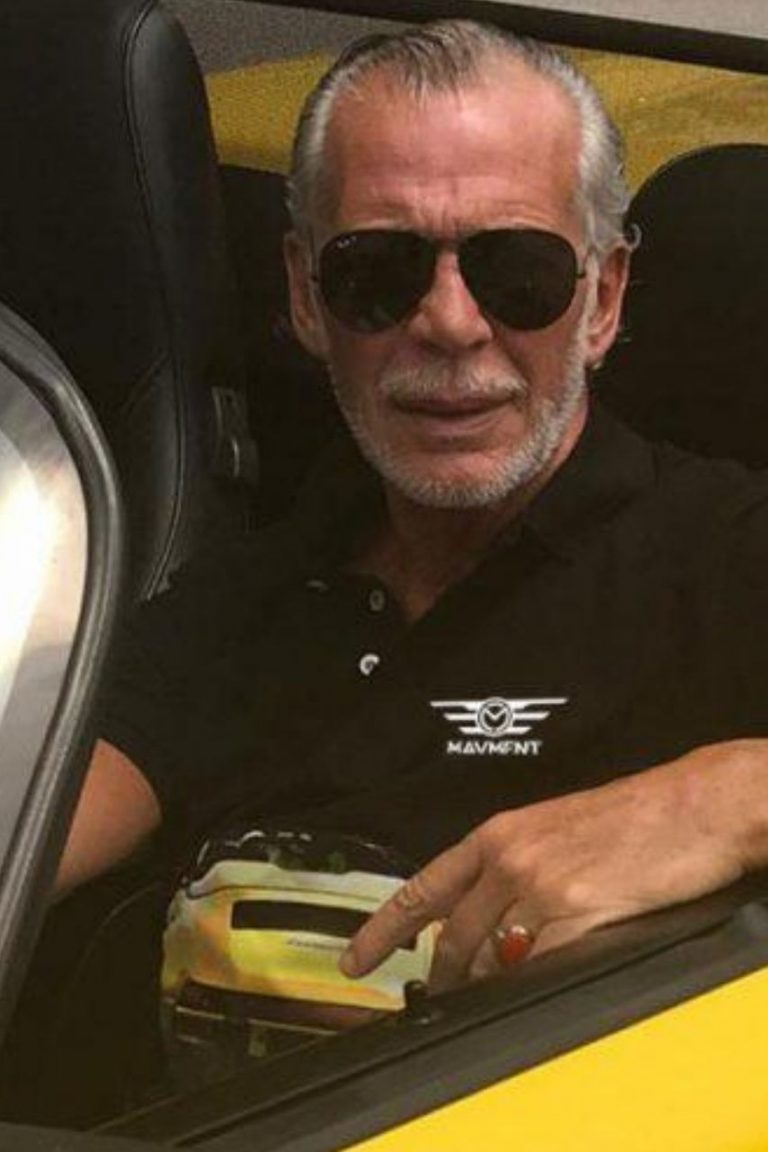

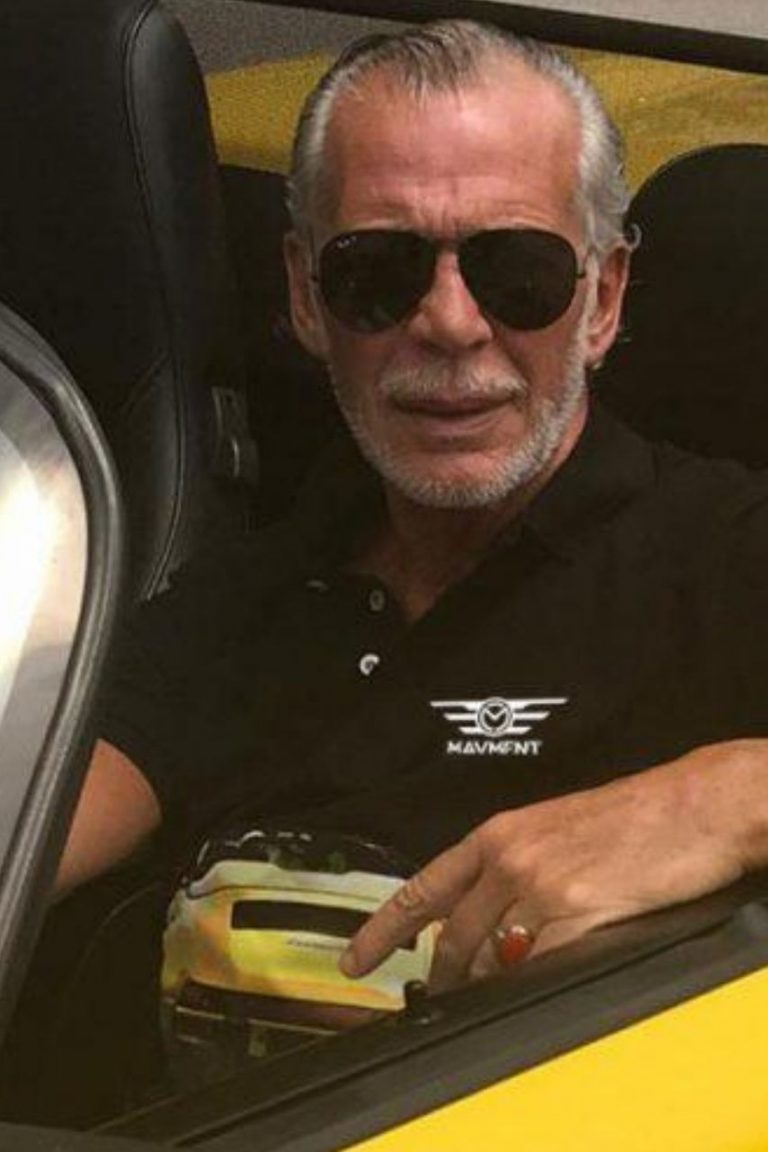

With his Giallina, a yellow Porsche Speedster, Carlo Mancuso, a 66-year-old entrepreneur from Padua, has become well known. We interviewed him for you!

Behind the crest Porsche, as is often the case with house cars, there is a story worth telling. Are you ready to meet it?

With his Giallina, a yellow Porsche Speedster, Carlo Mancuso, a 66-year-old entrepreneur from Padua, has become well known. We interviewed him for you!

Behind the crest Porsche, as is often the case with house cars, there is a story worth telling. Are you ready to meet it?

The classic car market is constantly growing, and historic cars now represent a safe haven asset. Let’s see how to choose.⠀

Mavment offers its spare parts excluding the passage of material through wholesale importers, thus lowering prices for the end buyer. Our company considers it indispensable, to provide cost-effective components of excellent quality, the result of meticulous selection of manufacturers and individual parts.⠀

Sign up for our Newsletter to stay up-to-date on promotions and latest news about the world of Porsche!