In recent years, 3D printing technology has profoundly transformed the automotive sector, enabling the production of lighter, more durable, and highly customizable components. Always at the forefront of innovation, Porsche has integrated this technology to optimize vehicle performance, reduce production times, and increase sustainability. From ultra-lightweight pistons to ergonomic seats and the reproduction of spare parts for classic cars, the Stuttgart-based company is redefining manufacturing standards through 3D printing.

This technology allows for the creation of complex geometries that would not be possible using traditional methods, such as honeycomb structures used in 3D-printed pistons. These structures reduce component weight without compromising strength while also improving heat dissipation and overall engine performance. Additionally, the use of innovative materials, such as advanced polymers and titanium alloys, enhances resistance and durability over time, offering increasingly high-performance solutions for Porsche customers.

Contenuti

How Porsche uses 3D printing

Integrating 3D printing into Porsche’s production process has opened up new possibilities in the design and manufacturing of vehicle components. From advanced mechanical parts to customizable interiors and spare parts for classic cars, this technology offers numerous advantages. Below, we analyze the key areas where Porsche is using 3D printing to improve vehicle performance and production efficiency.

High-performance mechanical components

One of the main areas where Porsche utilizes 3D printing is in the production of high-performance mechanical parts. A significant example is its collaboration with Mahle and Trumpf to develop ultra-lightweight pistons for the Porsche 911 GT2 RS. Thanks to this technology, the pistons are more robust and heat-resistant, enabling a power increase of up to 30 HP and greater energy efficiency.

Furthermore, Porsche is exploring the use of 3D printing for manufacturing electric motor housings. These components, designed to optimize heat dissipation and reduce overall weight, represent a significant advancement in the performance of electric vehicles. In addition to pistons and motor housings, Porsche is also studying the application of 3D printing in exhaust system components, with some prototypes already tested in laboratories to verify their thermal resistance and durability over time.

Other elements, such as camshafts and suspension components, have been redesigned to improve strength and longevity, contributing to greater efficiency in sports vehicles. The ability to design components with an optimized internal structure also reduces vibrations, enhancing the driving experience.

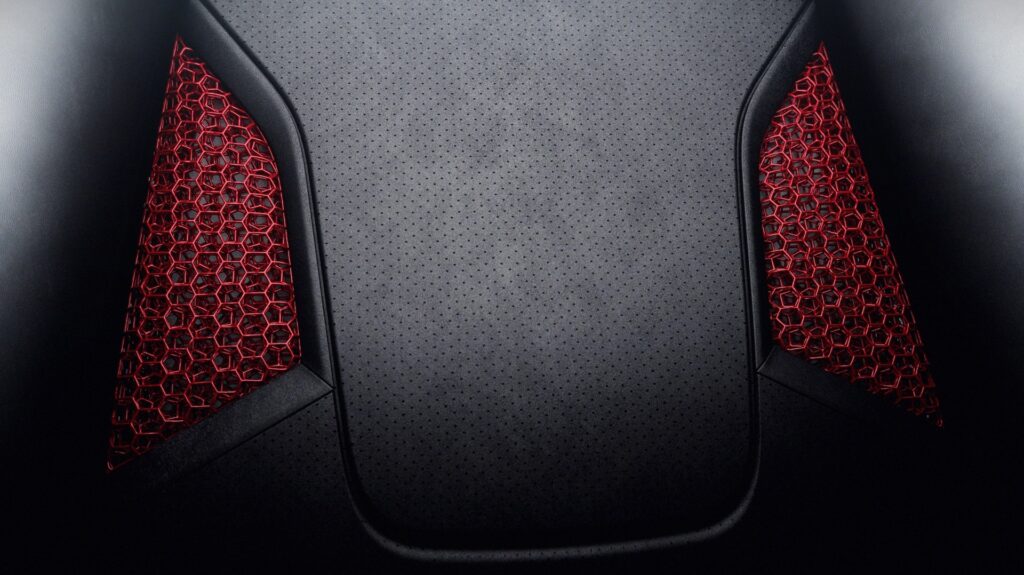

3D printed custom seats

Porsche has developed an innovative seat customization system using 3D printing. This solution allows customers to choose the level of seat rigidity, ensuring superior comfort and optimized support during sporty driving. Additionally, 3D-printed seats reduce the overall weight of the cabin, improving driving dynamics and fuel consumption.

Beyond seats, Porsche uses 3D printing for various interior components, including control panels, gear levers, and decorative inserts, offering an unprecedented level of customization. Some prototypes even feature integrated lighting elements within 3D-printed surfaces—an innovation that could be applied to door panels, dashboards, and even touch controls, enhancing both aesthetics and functionality in future Porsche models.

Manufacturing spare parts for classic cars

Another innovative application of 3D printing is the production of spare parts for classic cars. Many of these components are no longer available in traditional warehouses, making maintenance and restoration of historic models challenging. Thanks to 3D printing, Porsche can reproduce these parts on demand with exceptional precision, maintaining original specifications and ensuring the authenticity of classic vehicles.

This technology not only allows the recreation of otherwise unobtainable parts but also improves material quality, making components more durable without altering their original aesthetics. This is a huge advantage for collectors and restorers, who can now access high-quality spare parts to keep their vehicles in pristine condition. Additionally, Porsche is exploring the introduction of innovative composite materials to reproduce parts that surpass the original components in quality and longevity, ensuring greater reliability and reducing the need for future replacements. This approach not only preserves the historical value of vehicles but also ensures greater sustainability in spare part production, minimizing waste and production costs.

The advantages of 3D printing for Porsche

Porsche’s adoption of 3D printing is not limited to creating lighter and more efficient components; it also provides significant economic and environmental benefits. This technology helps reduce production times, enables unprecedented customization of vehicles, and enhances the sustainability of manufacturing processes. In the following sections, we explore in detail the key benefits that 3D printing is bringing to the Porsche world.

1. Reduced production time and costs

Thanks to 3D printing, Porsche can develop new components much faster than with traditional methods. This technology eliminates the need for molds and expensive equipment, allowing rapid testing of new designs and seamless implementation of improvements without production delays. Additionally, the ability to print components in-house reduces dependency on external suppliers, lowering logistical costs and increasing production flexibility.

2. Advanced customization

3D printing offers unprecedented opportunities for vehicle customization. From mechanical components to interior elements, customers can select unique materials, finishes, and configurations, transforming their Porsche into a truly one-of-a-kind model.

3. Sustainability and waste reduction

Compared to traditional production methods, 3D printing significantly reduces material waste and allows the use of more sustainable raw materials. Porsche is exploring the use of recycled and bio-based materials to further decrease environmental impact. The next step will be the introduction of biodegradable filaments for certain non-structural components, such as interior trim panels, door handles, and electronic device supports. These materials will not only reduce environmental impact but also improve overall vehicle recyclability.

The future of 3D printing in Porsche

Porsche continues to invest in 3D printing to expand its innovation potential in the automotive sector. With the evolution of electric mobility and new manufacturing technologies, 3D printing will play an increasingly central role in producing lighter, stronger, and more sustainable vehicles.

3D printing represents a revolution in the automotive industry, and Porsche is a prime example. However, large-scale adoption of this technology still presents challenges, including optimizing materials to ensure performance and durability comparable to traditional methods, controlling production costs, and standardizing processes for mass production. Addressing these factors will be essential for Porsche to fully leverage the potential of 3D printing in the automotive sector.